Industrial automation

Automatically controlling complex production processes or intelligently controlling production machines in a 24/7 production environment. We make that possible.

contact us read more

What is industrial automation?

Industrial automation is about the smart use of technology to make your production or business processes run more smoothly, reliably and safely. Think, for example, of machines that are controlled automatically, processes that are continuously monitored, or data that is collected automatically. Instead of doing everything manually, systems such as PLCs, robot arms or smart sensors take over this work. Often faster, more precisely and without a break.

For many SMEs, automation is the way to keep up in a competitive market. It ensures stable production, fewer errors and insight into how your processes really run thanks to real-time data. We help companies to design, build and implement smart automation solutions that suit the company.

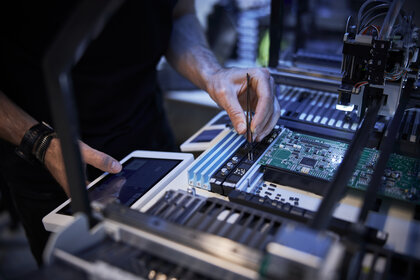

Hardware‑software integration

The success of industrial automation depends on the seamless integration of hardware and software. We develop control solutions in which hardware and software work seamlessly together. This gives you complete control over your production processes without vendor lock-in.

Challenges in the industry

The industry faces various challenges, but we offer solutions that help overcome the obstacles:

- Integration complexity: Connecting different systems and technologies.

- Flexibility and scalability: System solutions that grow with your business.

- Security and reliability: Protecting critical systems against cyberattacks and disruptions.

Customization and 24/7 reliability

We offer customized solutions that fully meet your specific needs. Moreover, we guarantee 24/7 reliability so your production can always continue.

Key technologies in industrial automation

We combine our expertise in hardware engineering with software knowledge to build powerful and reliable solutions. These are the core technologies that we regularly apply:

Programmable Logic Controllers (PLCs)

PLCs form the brain of many automated systems. They control machines, lines and installations. We work with Siemens and Beckhoff, among others, and ensure that your automation is robust, scalable and easy to maintain.

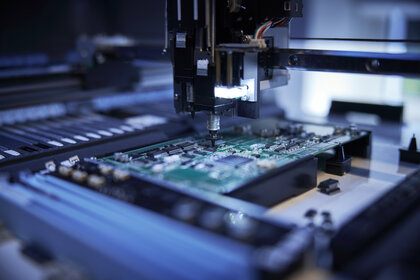

PCB design

Printed circuit boards are essential in every smart system. We design and build PCBs that work perfectly with your electronics and software. They form the basis of sensor technology, control modules or communication interfaces.

SCADA-systems

SCADA software gives you insight into what is happening within your production process. With dashboards and alerts, you can monitor real-time processes, log data and intervene quickly where necessary. We provide the hardware connection to your machines.

Industrial Internet of Things (IIoT)

With IIoT, we make machines and systems ‘connected’. This gives you access to real-time performance data, which helps with preventive maintenance or process optimization. We ensure that your hardware is suitable for data collection and secure communication.

AI and machine learning

These technologies help to recognize patterns in your process data. Think of predictive maintenance or automatic quality control. We ensure that the underlying hardware is suitable for these types of applications.

Robotics

Robots are increasingly taking over physical tasks. Think of repetitive work, assembly or packaging. Our hardware engineers develop the control and link it to the right software, safely and accurately.

Challenges that we solve

Industrial automation often involves complex questions:

- How do you connect new hardware to existing systems?

- How do you ensure safety, reliability and scalability?

- How do you keep systems understandable and usable for operators?

Our hardware engineers have the knowledge and experience to deal with this. We think along in architecture, develop custom and ensure that your team can work with the system without worries.

Ready to automate?

Do you want to take the first or next step in industrial automation? We are happy to think along with you, from idea to implementation. Let us know what you are facing or what you want to achieve, and we will provide the technical solution.

schedule a meetingHow can we help you?

Frequently asked questions

What does industrial automation entail at SST Hardware?

Which technologies does SST use in industrial automation?

How are hardware and software integrated at SST?

What challenges are recognized in the automation industry?

Does SST offer customized solutions?